Hydraulic oil delivers power, lubricates components, dissipates heat, and carries away contaminates. To perform these functions, hydraulic oils contain specific additives to enhance their ability to stand up to the pressure, temperature extremes, and other operating conditions to which they are subjected.

Most of the hydraulic systems are designed for operations involving maximum speed, pressure, and temperature. Analyzing the oil for contaminants and providing proper maintenance to the oil will reduce premature failure of the system. Therefore, it is so vital to consider oil viscosity, cleanliness and temperature as these features affect the function of hydraulic systems. Moreover, keeping these oil specifications in mind will ensure optimal, efficient system operations.

In case of disassembly of the subassembly from the hydraulic system, it is essential to check the cleanliness of fluid and the whole hydraulic system. The only accurate way to determine when hydraulic fluid needs to be changed is to perform an analysis on fluid samples, preferably from different points in the system.

Clean oil is essential for your equipment. Not only can the fluid seriously impact the components' performance and life expectancy but it also effects on the whole hydraulic system.

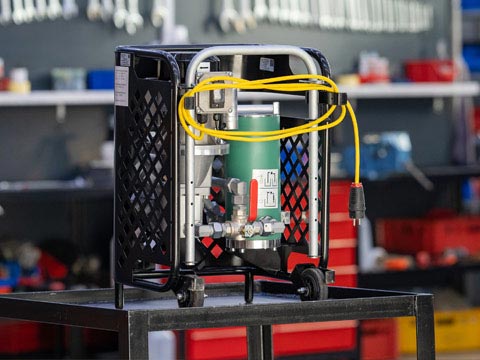

Our company provides customers with convenient oil testing and analysis service with the OPCom Portable Oil Lab. It is a mobile oil laboratory for service, with which the oil cleanliness and the oil condition in hydraulic and lubrication systems can be measured quickly and easily. We also perform oil filtration service using specialised filtration units. We highly recommend the oil filtration units which use the LIGHT LINE particle counter or particle counter and humidity sensor Argo-Hytos.

OUR COMPANY HAS BEEN HONORED WITH THE CERTIFICATE OF THE LEADING MANUFACTURER, ARGO-HYTOS POLAND.

Auctions

Auctions